Blog

Return to Blog »

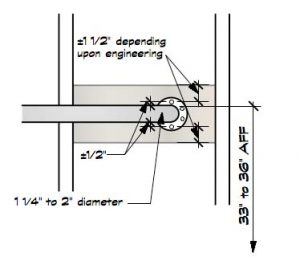

Janis Kent, FAIA, Architect, CASp © April, 2020 Recently something has come to my attention – namely what are the requirements for blocking for grab bars? When I review drawings I typically see the bar location specified and then a graphic rectangle to show diagrammatically the extent of the backing. But I have rarely seen the size of the actual blocking or its specific location AFF and attachment. When I enquired out in the field, what is the standard for blocking, I heard that a rule of thumb is for a 2×6 centered at ±36″ AFF. Construction for accessibility is particular and an installation tolerance should also be specified. Since blocking is hidden in the wall, it becomes extremely critical to provide for a range of grab bar installation heights the blocking can accommodate. Another consideration is that grab bars are typically installed after finishes go in, whereas in residential, they are installed within dwelling units upon request which can be many years later. So is a 2×6 adequate and at what height? I explored parameters a 2×6 should be placed AFF to provide the greatest range for future grab bar installation. Different trades stated typical screw attachments for blocking are inset 1½” from both edges of wood blocking. So, if we take a mid-sized grab bar with a diameter of 1½”, add another ½” at the top and bottom for the flange attachment, we have an overall height of 2½”. When 3″ (1½” inset from top and bottom for blocking attachment) is added, it totals a height of 5½”. Since a 2×6 has an actual dimension of ±5½”, there is no buffer for blocking height requirements. So this rule of thumb is not adequate and should not be used. With this example, there is also no tolerance for grab bar installation height either and the bars need to be limited to 1¼” to 1½” diameter only. In addition, we will need to know later exactly where the bar is to be installed. So a 2×6 is not adequate for blocking and installation of grab bars because it does not provide for the full range of installation heights and bar sizes allowed – this installation is just too exacting to be executed in a two step process by two different trades. I have also heard about rules of thumb for using a 2×8 or 2×10 or even ¾” structural plywood sheets over blocking. While this can provide for more installation tolerance and buffer, dependent upon the actual height at which the blocking is provided, it would still need to be engineered. The above comments are only tolerances for installation heights. Since grab bars, their fasteners, and supporting structure are to withstand a minimum of 250 lbs force, whether vertical or horizontal along any part of the bar, this is required to be engineered, not only for the blocking but also for the attachments. While a hidden element, it is very important. If it can not withstand the required forces of at least 250 lbs, the bar can come ripping out of the wall and create a very serious accident. My point is NOT to size and install blocking to minimums, but rather to engineer it like any other structural member. Lack of tolerance and buffer is a recipe for disaster when the blocking within the wall is hidden from the installer. In summary, blocking is a critical element for safety and installation. It needs to be sized and detailed on engineering drawings with clear cross referencing with the architecturals to assure coordination and avoid mistakes. And the details will differ depending upon whether wood or steel framing. Also, providing documentation of the as-built condition during rough framing is very helpful for subsequent trades and inspectors. It should consist of photographs with a sketch showing size and centerline of blocking AFF which eliminates guess work and assumptions. This is all very technical but quite important for life safety. It should not be left to rules of thumb – avoid the perfect storm where assumptions can lead to grab bars not being sufficiently anchored. Be aware that your local City or County may have additional requirements that are more restrictive than the State or Federal requirements. Also, this article is an interpretation and opinion of the writer. It is meant as a summary – current original regulations should always be reviewed when making any decisions. © Janis Kent, Architect, FAIA, CASp April, 2020 Inquire About Consulting ServicesBlocking for Grab Bars – What is There to Know?

Installation Height

Structural Support

Related: Download “Restrooms – Curated Collection of Articles from the Stepping Thru Accessibility Blog”

Contact us for more information about our consulting services

Contact us for more information about booking public or seminars on this topic or others